Currently Empty: ₹0.00

Handmade Soap

Handmade Soap

Handmade Soap

Handmade Soap

Journal

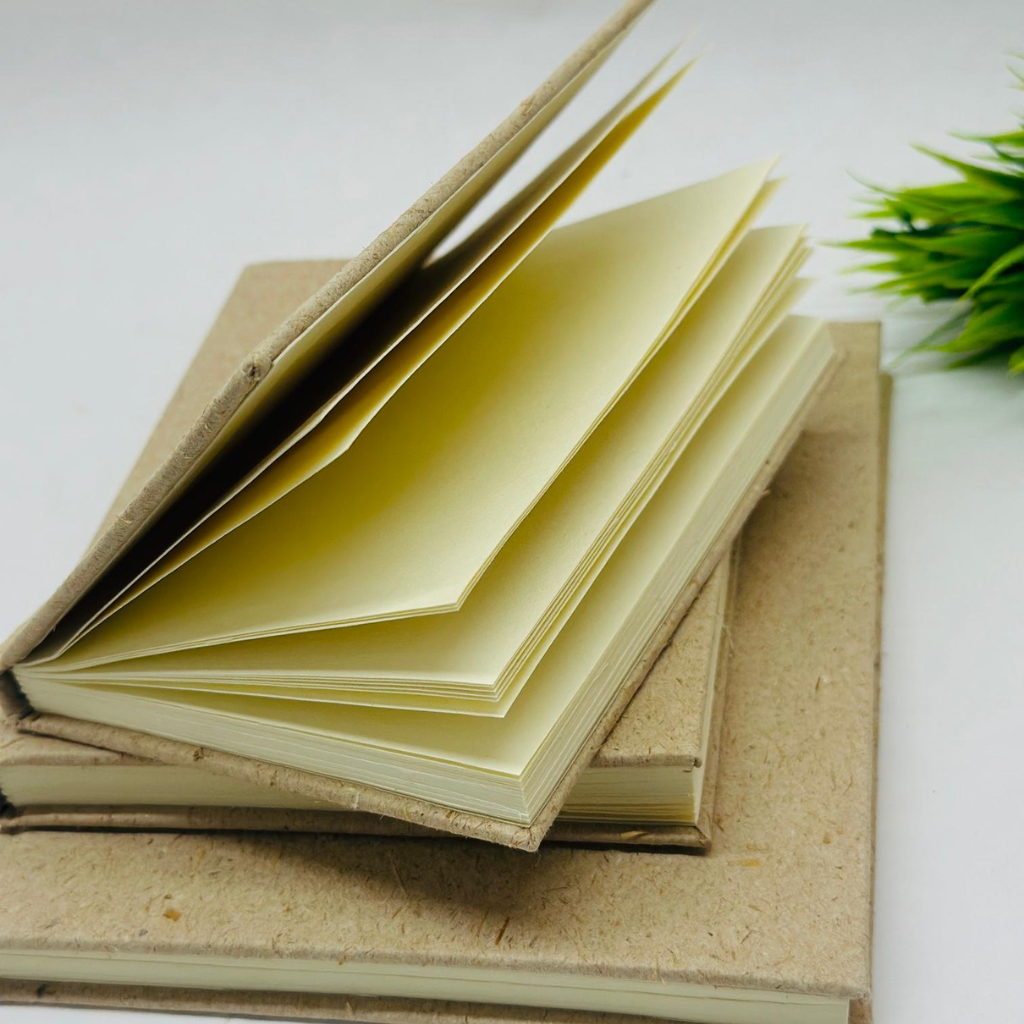

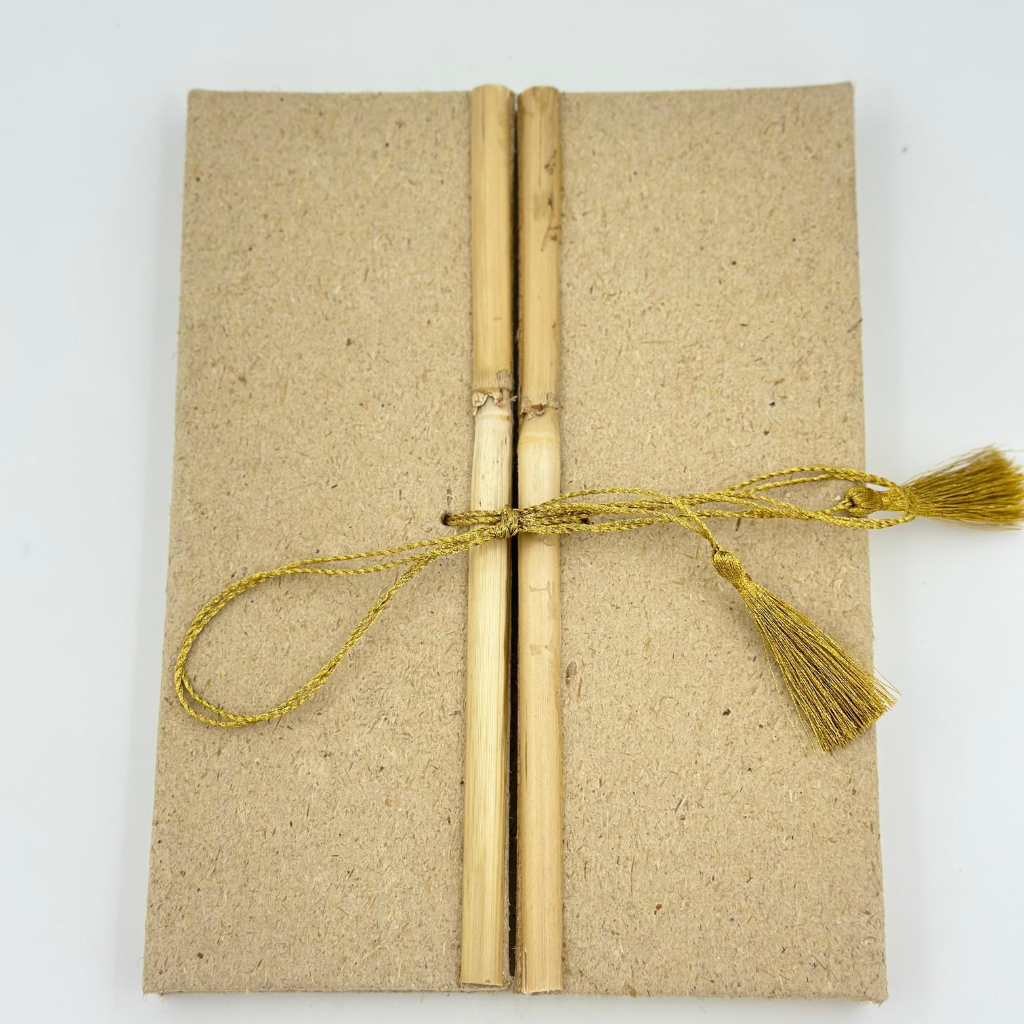

Handmade Farmer Paper Journal

This Handmade Farmer Paper Journal is thoughtfully crafted from eco-friendly paper made using agricultural waste fibers, turning nature’s by-products into something beautiful and meaningful. Each page is handmade by skilled artisans, giving the journal a unique texture and natural character that no machine-made paper can replicate.

100% Eco-Friendly

Save Tree

Natural Ingredients

Organic

Our Tranding Product

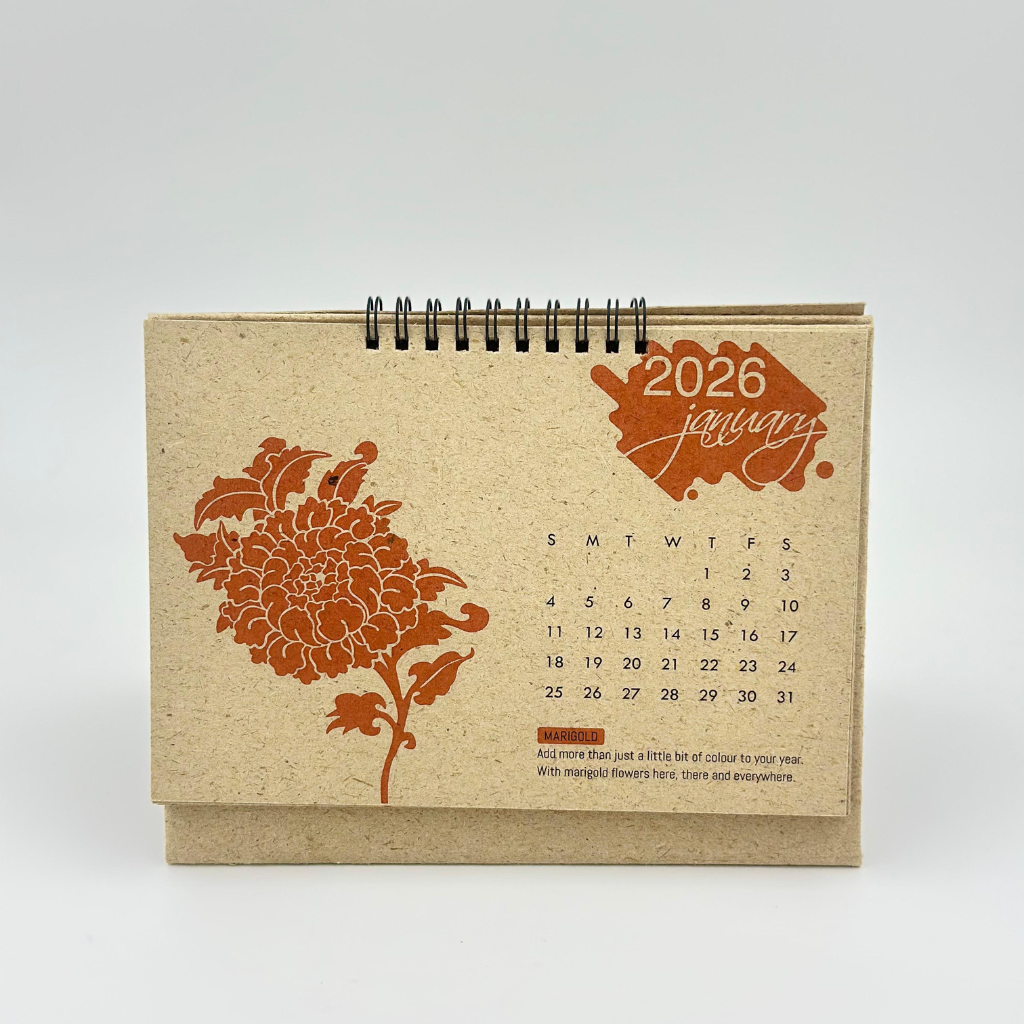

Handmade Farmer Paper Calendar

Celebrate each day with purpose and craftsmanship through our Handmade Farmer Paper Calendar. Thoughtfully created using eco-friendly, recycled farmer paper, this calendar reflects a commitment to sustainability and traditional artistry. Each page carries a natural texture and earthy tone, making every month feel warm, organic, and unique.

Perfect for homes, offices, or gifting, the calendar blends functionality with conscious living. The handmade paper is durable, biodegradable, and free from harmful chemicals—supporting rural artisans while reducing environmental impact. More than just a way to track dates, this calendar is a reminder to live mindfully and stay connected to nature throughout the year.

Farmer Paper Products

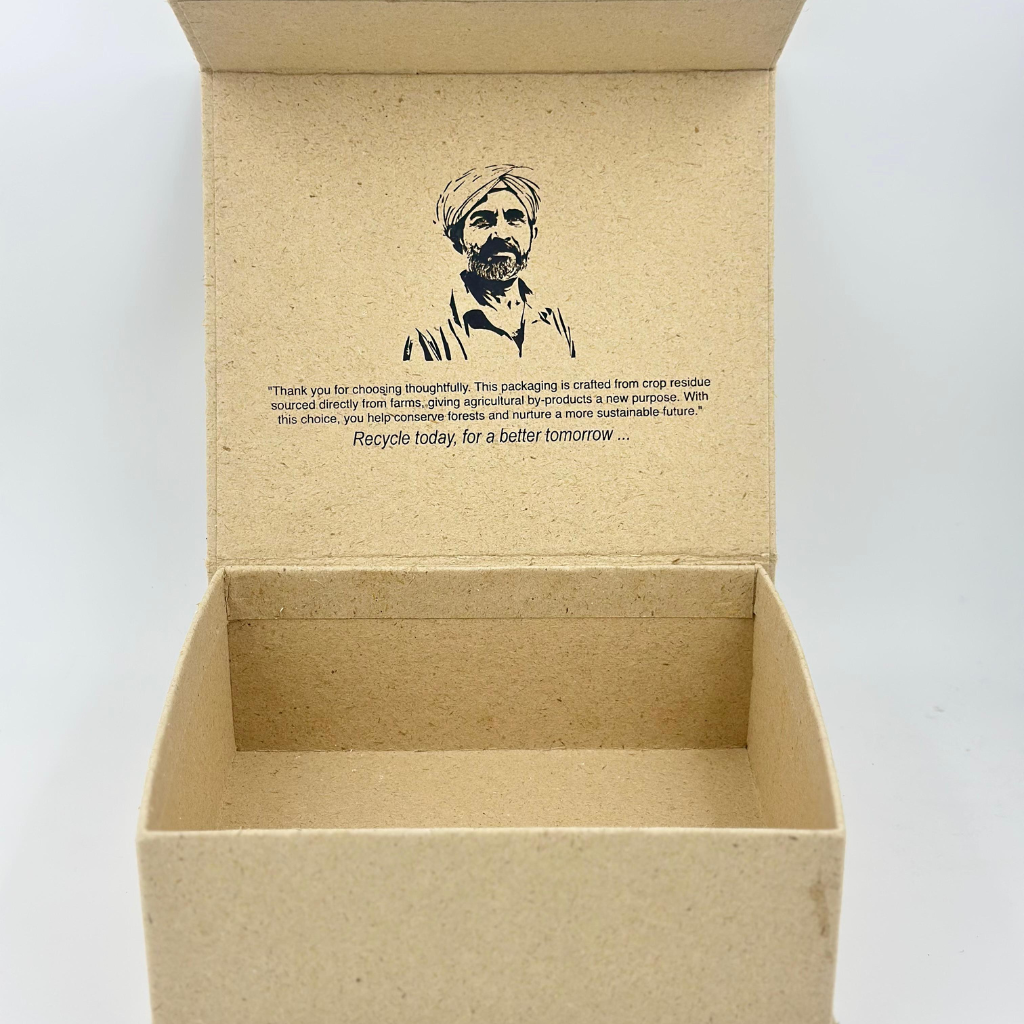

Manufacturing of Handmade Paper from Agricultural Waste

The manufacturing of handmade paper from agricultural waste, particularly rice straw, is an eco-friendly and sustainable process that transforms farm residue into valuable paper products. Rice straw is abundantly available in rice-producing regions and is often treated as waste after harvesting. Traditionally, this agricultural residue is burned in fields, causing severe air pollution and loss of potential resources. By using rice straw as a raw material for handmade paper, this waste is converted into an environmentally responsible product while also providing additional income opportunities for farmers and rural artisans. The process not only helps reduce environmental damage but also promotes circular economy principles by reusing natural resources efficiently.

Rice straw is an excellent raw material for handmade paper due to its high cellulose content. Cellulose is the primary component required for paper making, as it provides strength, flexibility, and durability to the paper. Compared to wood pulp, rice straw contains less lignin, which makes it easier to process using low-chemical and low-energy methods. This characteristic makes rice straw especially suitable for handmade paper production, where traditional, non-industrial techniques are preferred. The use of rice straw also reduces dependence on trees, helping conserve forests and biodiversity.

The manufacturing process begins with the collection of rice straw after the harvesting season. Once the rice grains are removed, the leftover straw is gathered from the fields. Farmers usually dry the straw naturally under the sun to reduce moisture content, which helps prevent fungal growth and decay. Proper drying is essential to ensure consistent quality during paper production. After drying, the straw is bundled and transported to handmade paper units or workshops located near agricultural regions to minimize transportation costs and carbon emissions.

Once the rice straw reaches the manufacturing unit, it undergoes a cleaning and sorting process. This step involves removing dust, soil, stones, and other unwanted materials mixed with the straw during harvesting. Clean raw material is crucial for producing high-quality handmade paper. The straw is then cut into small pieces, usually ranging from 2 to 5 centimeters in length. Cutting the straw into smaller pieces increases the surface area, allowing better penetration of water and chemicals during the pulping stage.

The next step is soaking the cut rice straw in water. Soaking softens the fibers and helps break down natural bonding agents present in the straw. This process may take anywhere from 24 to 48 hours, depending on the thickness and dryness of the straw. In traditional handmade paper units, soaking is done in large tanks or vats filled with clean water. This step significantly reduces the amount of energy required during cooking and pulping, making the process more efficient and environmentally friendly.

After soaking, the rice straw is cooked to separate the cellulose fibers. Cooking is usually done using mild alkali solutions such as sodium hydroxide or natural alternatives like soda ash. The purpose of cooking is to remove lignin, hemicellulose, and other non-cellulosic components from the straw. Compared to wood pulp processing, rice straw requires less chemical usage, making the process less harmful to the environment. The cooking process is carried out at controlled temperatures to ensure the fibers are not damaged and retain their natural strength.

Once cooking is complete, the straw fibers are thoroughly washed with clean water to remove residual chemicals and impurities. Washing is a crucial step, as leftover chemicals can weaken the paper and affect its color and texture. Multiple washes may be required to achieve the desired purity of pulp. The wastewater generated during washing can be treated and reused for irrigation or non-potable purposes, further enhancing the sustainability of the manufacturing process.

The washed fibers are then beaten or pulped to achieve the required consistency. Beating is a mechanical process that helps separate fibers, increase bonding potential, and improve the strength of the paper. In handmade paper units, beating is often done using traditional beaters or modern low-energy machines. The duration of beating determines the final texture of the paper—short beating produces rough, textured paper, while longer beating results in smoother and finer sheets. This flexibility allows artisans to create a wide range of handmade paper products.

Once the pulp is ready, it is mixed with water in a large vat to create a uniform slurry. At this stage, natural additives may be introduced to enhance the paper’s properties. These additives can include natural starch for strength, plant-based sizing agents for water resistance, or natural dyes for color. Since handmade rice straw paper focuses on eco-friendliness, synthetic chemicals are generally avoided. The slurry is continuously stirred to keep the fibers evenly suspended in water.

Sheet formation is the most distinctive and artistic step in handmade paper manufacturing. Artisans use a mould and deckle—a wooden frame fitted with a fine mesh—to scoop the pulp slurry from the vat. As the mould is lifted, water drains through the mesh, leaving an even layer of fibers on the surface. The artisan gently shakes the mould to distribute fibers uniformly, ensuring consistent thickness. This manual process gives handmade paper its unique texture, deckled edges, and natural variations that differentiate it from machine-made paper.

After forming the sheet, it is transferred onto a felt or cotton cloth in a process called couching. Multiple sheets are stacked alternately with cloth layers to form a pile. This stack is then pressed to remove excess water. Pressing can be done using wooden presses, screw presses, or hydraulic presses, depending on the scale of production. Proper pressing improves fiber bonding, increases paper strength, and reduces drying time.

Drying is the next important stage in the manufacturing process. Pressed sheets are carefully separated and dried using natural or controlled methods. Traditional handmade paper units often rely on sun drying, where sheets are hung on ropes or placed on drying racks. Sun drying is energy-efficient and enhances the natural color and texture of rice straw paper. In regions with high humidity or limited sunlight, drying rooms with controlled airflow may be used to ensure consistent results.

Once dried, the paper sheets undergo finishing processes to enhance their appearance and usability. Finishing may include surface sizing, polishing, or calendaring. Surface sizing involves applying a thin layer of natural starch or gelatin to improve ink absorption and writing quality. Polishing can be done using smooth stones, shells, or wooden tools to achieve a smoother finish. Depending on the intended use, paper can be left rough and textured or finished to a more refined surface.

Quality inspection is an essential step before the paper is packaged or converted into products. Each sheet is checked for thickness, strength, color consistency, and defects. Handmade rice straw paper naturally exhibits slight variations, which are considered a mark of authenticity rather than flaws. Sheets that do not meet quality standards are often recycled back into the pulping process, ensuring minimal waste generation.

Handmade paper produced from rice straw is versatile and used for various applications. It is commonly used for stationery, notebooks, journals, calendars, envelopes, gift wrapping, wedding cards, art paper, and eco-friendly packaging. Due to its natural texture and earthy appearance, rice straw paper is especially popular among artists, designers, and environmentally conscious consumers. Its biodegradable and recyclable nature makes it an ideal alternative to conventional paper products.

The social impact of rice straw handmade paper manufacturing is significant. The industry provides employment opportunities to rural communities, artisans, and women’s self-help groups. Since the process is labor-intensive rather than machine-driven, it supports skill development and traditional craftsmanship. Many handmade paper units operate as small-scale or cottage industries, contributing to rural development and economic stability.

Environmentally, the benefits of using rice straw for handmade paper are substantial. It reduces air pollution caused by stubble burning, conserves forests by reducing wood consumption, and lowers carbon emissions through low-energy production methods. The use of biodegradable materials and minimal chemicals further reduces the ecological footprint of the manufacturing process. Additionally, the wastewater generated can be treated and reused, promoting responsible water management.

In conclusion, the manufacturing of handmade paper from agricultural waste such as rice straw is a sustainable, eco-friendly, and socially responsible process. It transforms an underutilized waste material into a valuable product while addressing environmental challenges like pollution and deforestation. Through traditional craftsmanship, minimal chemical usage, and renewable raw materials, rice straw handmade paper represents a harmonious balance between nature, economy, and culture. As demand for sustainable products continues to grow, rice straw handmade paper stands as a powerful example of how agricultural waste can be converted into meaningful and beautiful products.